Our UniService

ASEP Services Ltd has the experience to source, supply, and install a wide range of spare parts for many of the common ancillary machines. We are able to do this because we have over 30 years of experience serving the plastics industry, during the time we have worked with a large array of ancillary equipment and suppliers and have accumulated a large data base of technical information, this couples with years of searching the UK market for genuine aftermarket spare parts allows us to serve our customers in a unique way.

We call this UniService, an independent impartial cost-effective service.

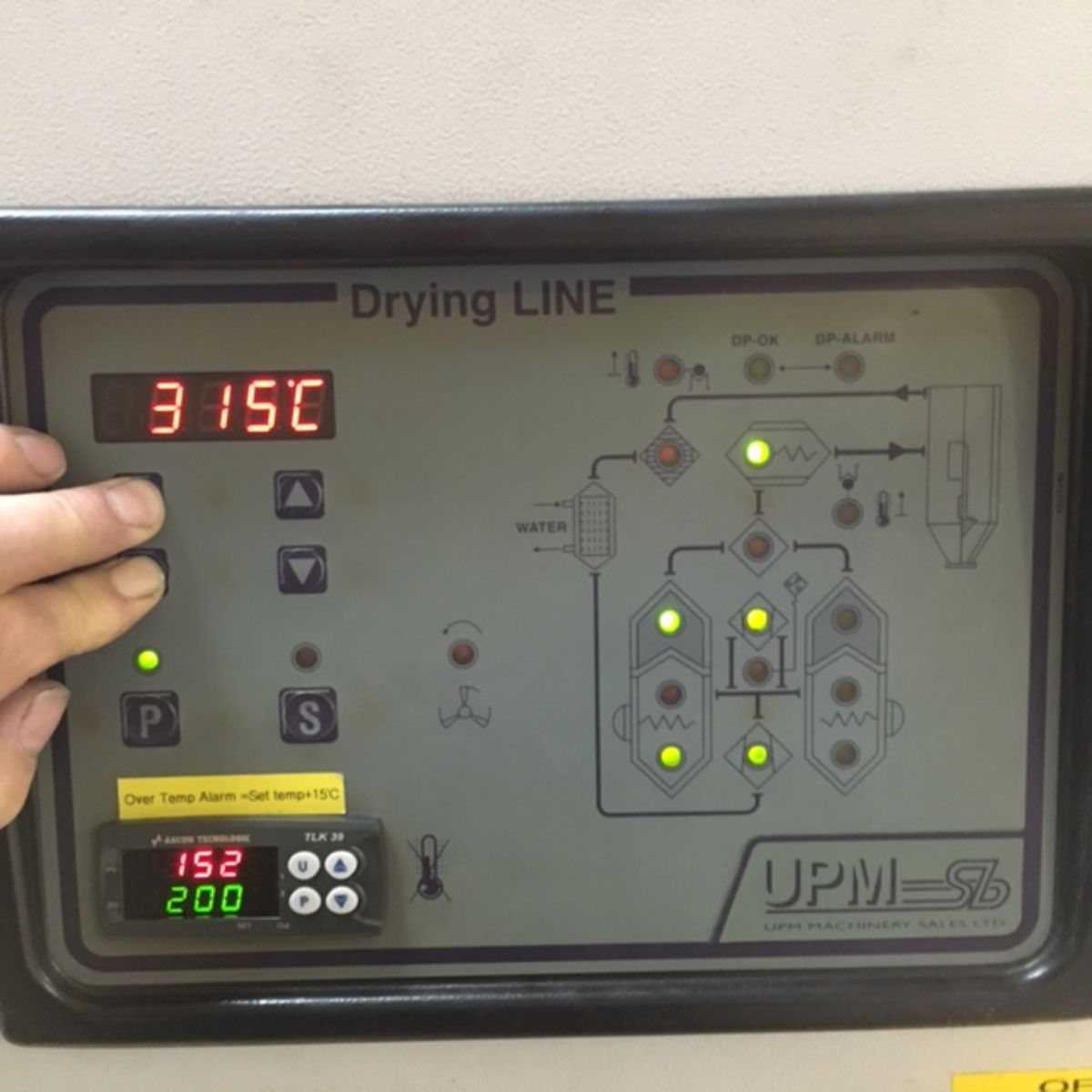

Dryers

- Dehumidifying dryer dewpoint and temperature calibration

- Cycle checks

- Full on site repair service

- Desiccant replacement.

- Performance certificate

- Examination of dryer suitability for the moulding process.

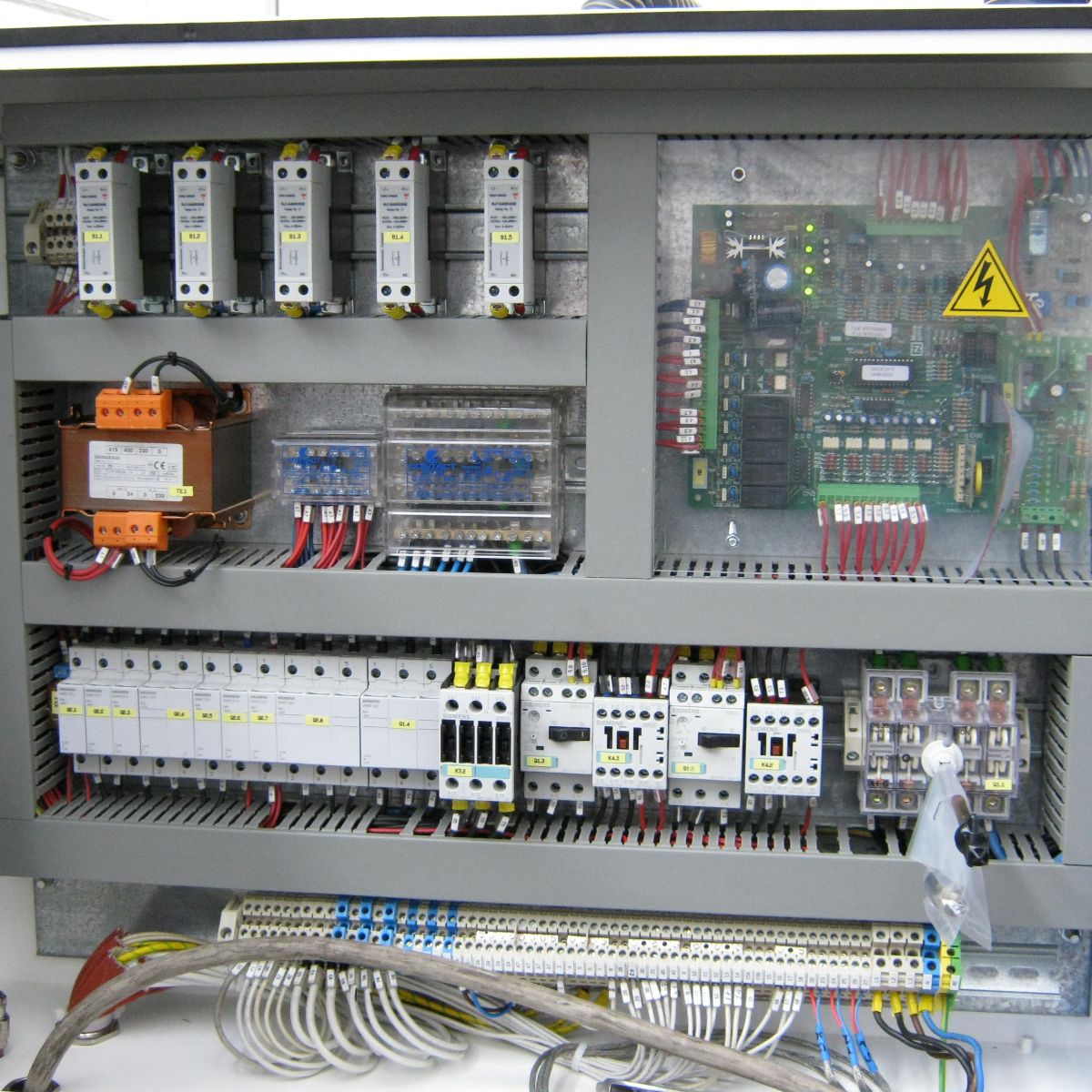

PLC and HMI Control Panels

- Complete control panel replacement

- Fault finding

- Extensions and modifications

- Training and set up services

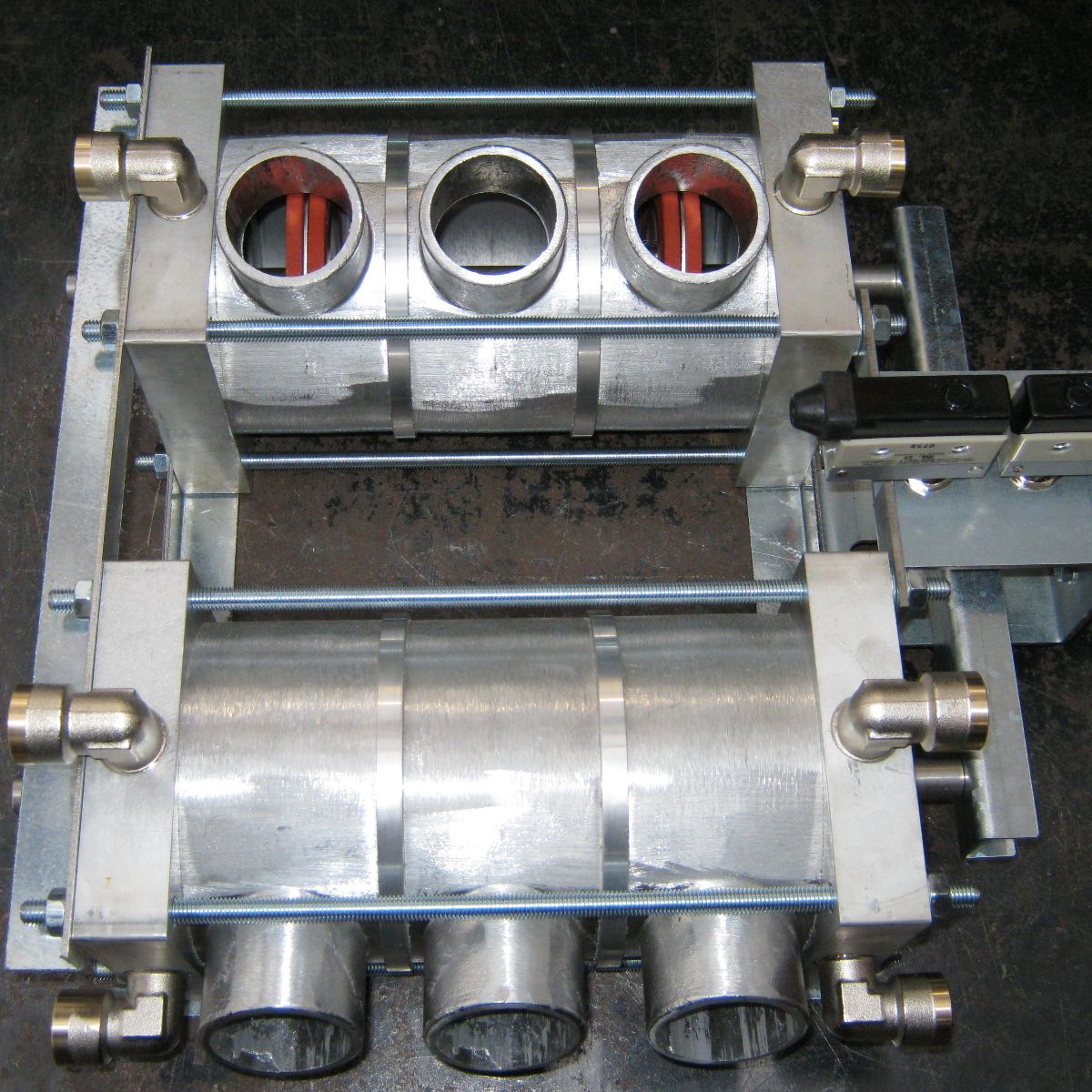

Gravimetric and Volumetric Dosers

- Load cell weight calibration

- Motor and pneumatic spares

- Moulding machine integration

Mould Heaters / TCU

- Temperature calibration

- Pump heater and electrical control repairs

- Set up and training

Hot Air Dryers

- Temperature calibration

- Fan motor and electrical control repairs

Granulators

- Knife sharpening and replacement

- Safety circuit checks and repairs

- Bearing, belt and general repairs

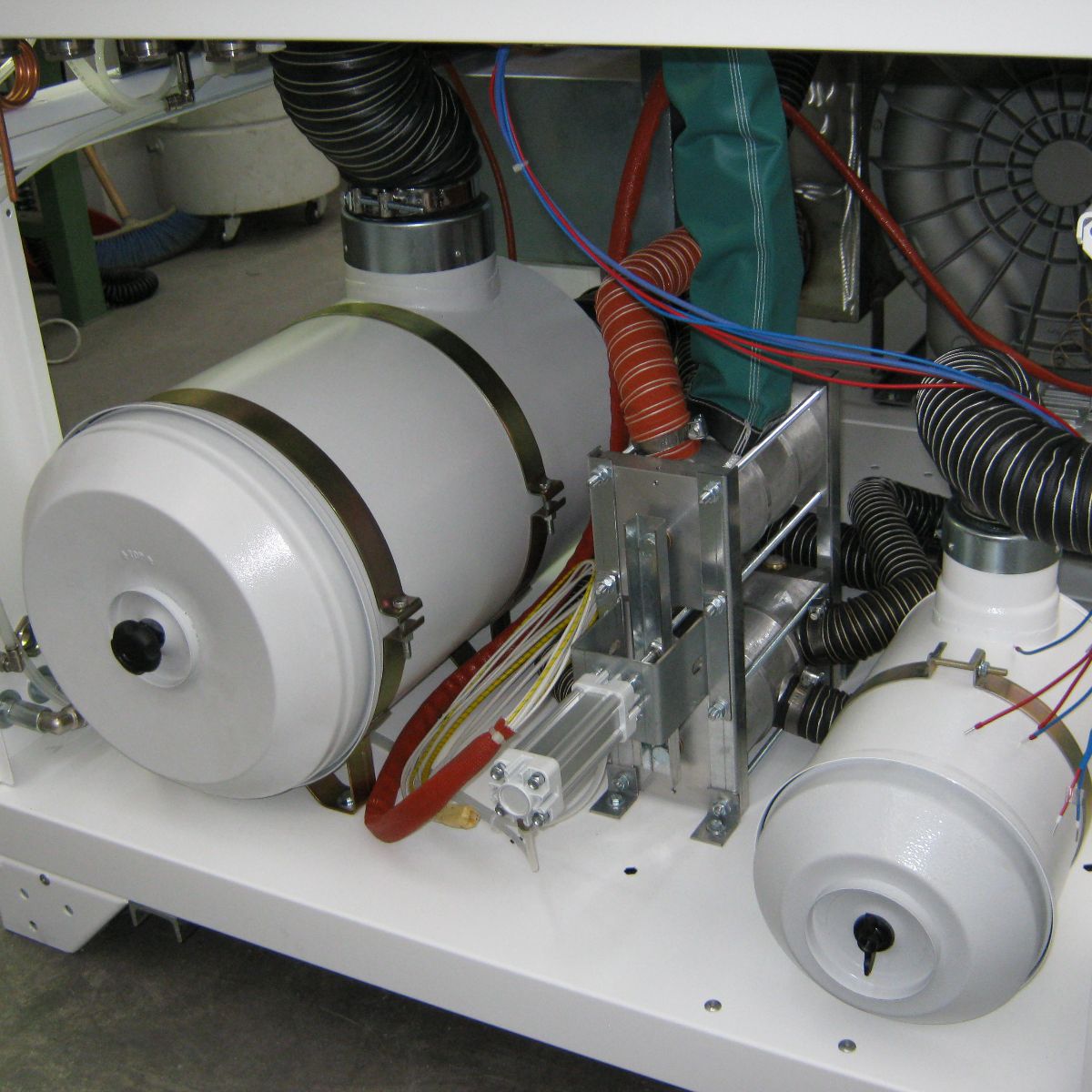

Central Material Handling Systems

- Vacuum and material pipework inspection and repair

- Vacuum receiver inspection and repair

- Vacuum pump examination repair service or upgrade

- Central filter and filter cleaning functions checked, replaced, or repaired

- Flexible hoses checked

- System set up check including all operating parameters and material flow, as well as checks for throughput suitability

ASEP`S Simpro Record Keeping System for all equipment serviced

- All calibration test results

- All cycle performance results

- Spares used

- Service frequency

- Available to all ASEP customers for their quality records

ASEP engineers have detailed knowledge and experience in material handling equipment and how to keep them in optimum working condition to make sure you are producing quality mouldings.

We specialize in the service and repair of dehumidifying dryers as well as advising on their use and suitability for your moulding process, we also focus on your material handling system to ensure the constant delivery of dry material to your process machines, add on our experience in colour dosing and blending, granulation, mould heating, and PLC controls and software and you can see ASEP has your material processing needs covered.